-

Structural materials in the future advanced nuclear facilities have to withstand harsh environments, such as high He accumulation, strong displacement damage and heat flux. Materials with excellent service performance is desired to meet the safe and efficient operation of the reactors. Due to their high resistance to radiation swelling and creep, low thermal expansion coefficient and low activation, ferritic/martensitic (F/M) and oxide dispersion strengthened (ODS) steels are envisaged as promising candidate structural materials for the next-generation (Generation Ⅳ) and fusion reactors[1-3]. The response of these two materials to neutron irradiation has been widely studied. However, it is difficult to analyze the effect of a single factor in neutron irradiation accurately due to variable parameters, including damage rate, temperature and He production rate[4]. In contrast, He ions implantation has been proved to be a better choice to study the effect of He in materials. It has been demonstrated that He can occupy the center of vacancy to form He-V complex during irradiation. The He-V complex can further involve into bubbles or voids, resulting in swelling, hardening, embrittlement and reduction of creep properties of material[5-6]. However, the behavior of He is easily affected by nanostructures in the material at elevated temperature, such as grain boundary, precipitation phase, dislocation and nano-oxide particles[7]. By introducing various nanostructures into the materials, the swelling can be effectively suppressed or delayed. In this study, the behaviors of He bubbles in a novel type of F/M steel (SIMP steel) and two kinds of ODS steels (MA956 and Eurofer-ODS steels) with various nanostructures have been investigated by high fluence of He ions implantation. The aim is to reveal the effect of nanostructures on evolution of He bubbles in F/M and ODS steels at the high fluence of He implantation.

-

The materials employed in the present experiment were a new F/M steel-SIMP designed by Institute of Modern Physics(IMP) and Institute of Metal Research(IMR), Chinese Academy of Sciences(CAS), and two kinds of ODS steels, namely commercial MA956 and Eurofer-ODS steels. Detailed thermal treatment and chemical composition for each type of steel are summarized in Table 1. It is worth further clarification that, as a new type of domestic independently developed martensitic steel, SIMP steel has better oxidation resistance and liquid metal corrosion resistance than other traditional F/M steels with the high content of Si. Moreover, the low activation characteristics of SIMP steel are realized via replacing both Mo with W and Nb with Ta.

Table 1. Details of chemical composition of SIMP, Eurofer-ODS, and MA956 steels (%).

Steels Fe Cr C Mn S W V Ta Si P Y2O3 Ni Al Ti Mo SIMP#1 Bal 10.24 0.22 0.52 0.0043 1.45 0.18 0.12 1.22 0.004 Eurofer-ODS#2 Bal 8.70 0.11 0.44 0.004 1.00 0.19 0.10 0.30 MA956#3 Bal 19.93 0.023 0.09 0.008 0.008 0.006 0.51 0.04 4.75 0.39 0.02 #1 SIMP: normalized at 1 040 °C for 30 min and tempering at 760 °C for 90 min.

#2 Eurofer-ODS: normalized at 1 150 °C for 60 min, tempering at 750 °C for 120 min.

#3MA956: canned and extruded at 1 100 °C, hot-rolled for 240 min, reheating to 1 100 °C for 30 min, hot-rolled.The samples used for the ions implantation were cut into dimensions of 3 mm×3 mm×1 mm with diamond wire cutting machine. One surface of each sample was ground into smooth surface with gradually refined sandpaper from 600 to 2 500 grades, and then was polished to a mirror-like surface by using vibration polisher.

-

The implantation experiment was conducted in the Low Energy heavy ion Accelerator Facility(LEAF) at IMP, CAS. All of the materials were injected by 2 MeV He ions to a fluence of 1×1017 ions/cm2 at 500 and 600 °C. The detailed implantation parameters are shown in Table 2. The implantation temperature with a fluctuation of about

$ \pm $ 5 °C was monitored by two thermocouples near the sample. The current intensity was measured by two Faraday tubes in real time and remained at 30 μA.Table 2. Detailed parameters of He ions implantation experiment.

Sample Ion Energy/

MeVTem/℃ Fluences/

(ions·cm−2)SIMP/EU-ODS/MA956 He 2 500 1×1017 600 The depth distribution of both radiation damage level and He ions deposition concentration are obtained by SRIM 2013 calculations in “quick Kinchin-Pease calculation” mode[8]. During SRIM calculation, the density of target materials is 7.87 g/cm3, and the displacement threshold energies of both Fe and Cr are set as 40 eV[9].

-

The cross-sectional TEM slices with thickness of about 70 nm were prepared by dual beams focused-ion beam(FIB) lift-out method. The microstructures were observed under the bright field image model of FEI Tecnai F20 TEM operated at 200 kV.

Irradiation induced swelling for a selected region can be calculated by Eq. (1):

$$S = \frac{{\Delta V}}{{V - \Delta V}} \times 100{\text{%}} ,$$ (1) where V is the volume of the selected region after irradiation. ∆V represents the relative change of the volume caused by bubbles in the region, that is the total volume of the bubbles in this region.

-

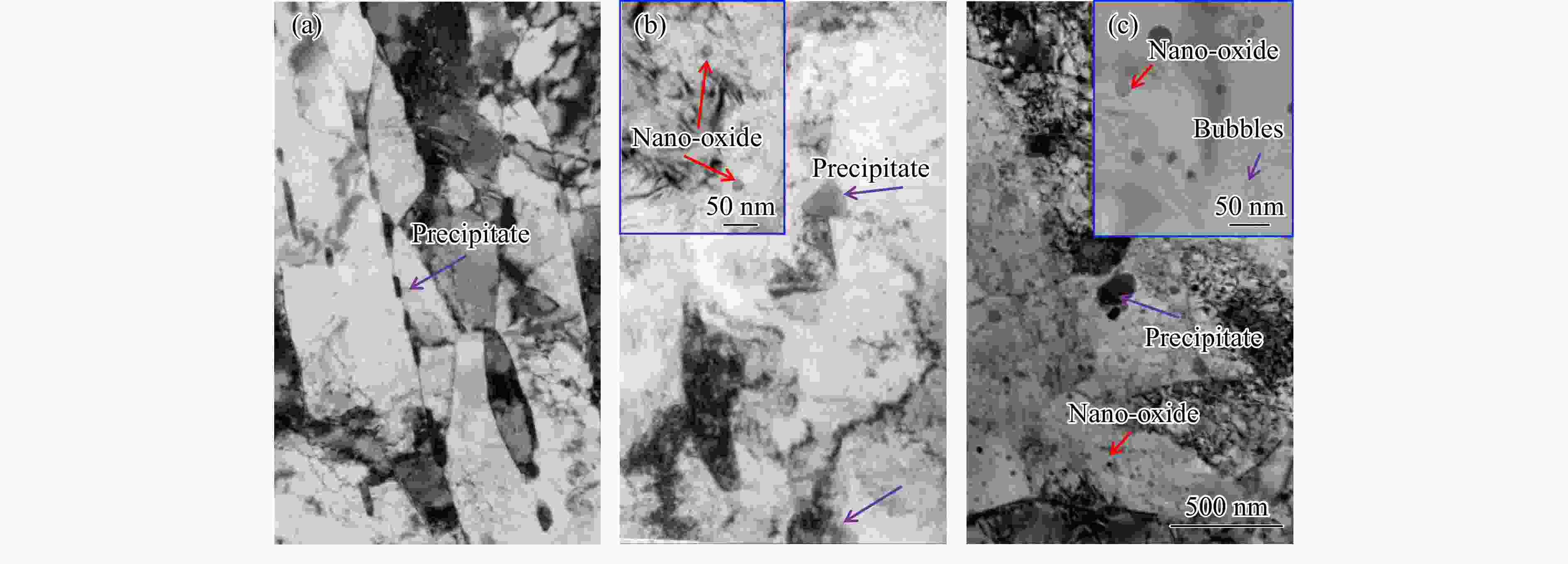

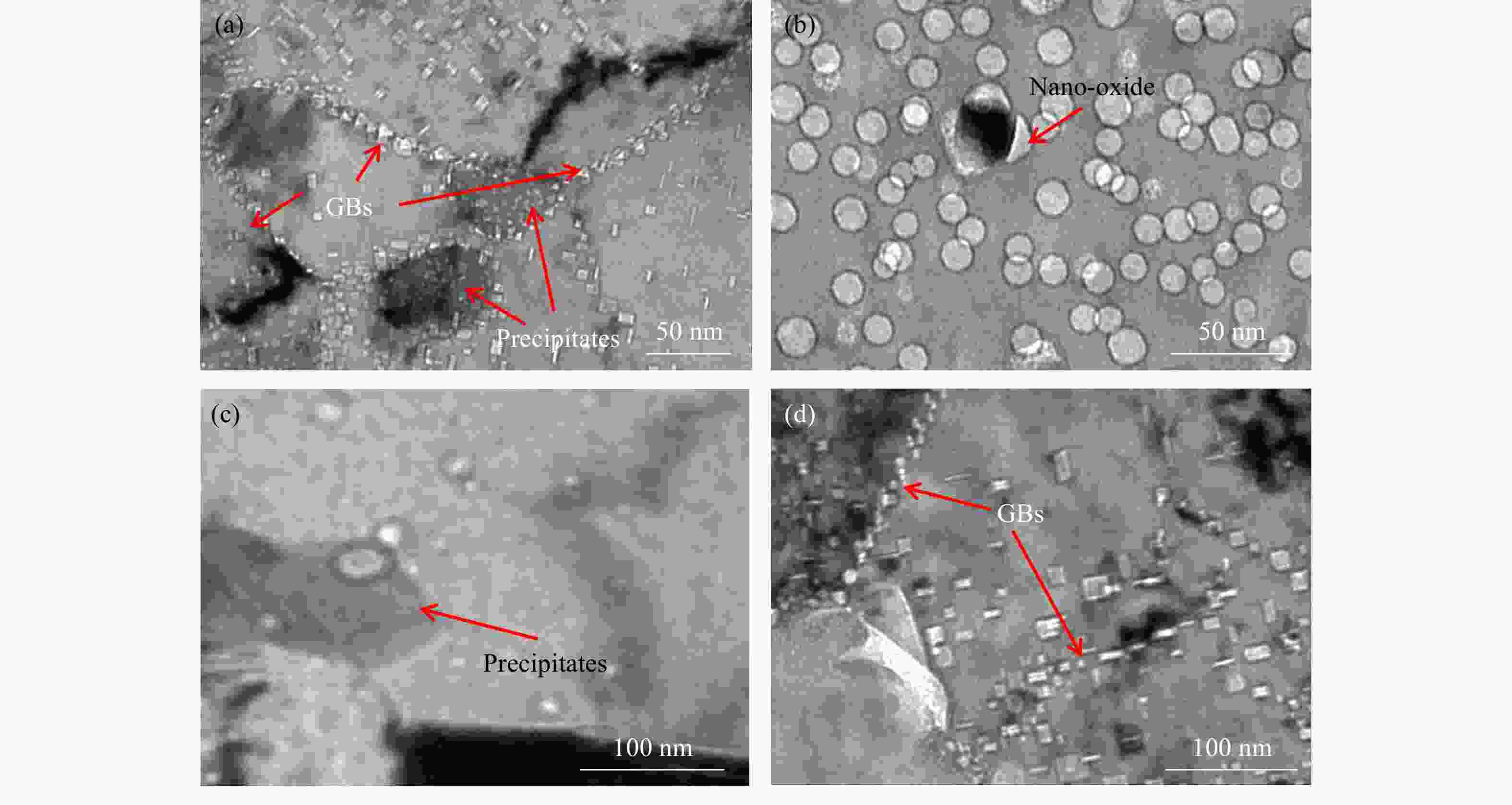

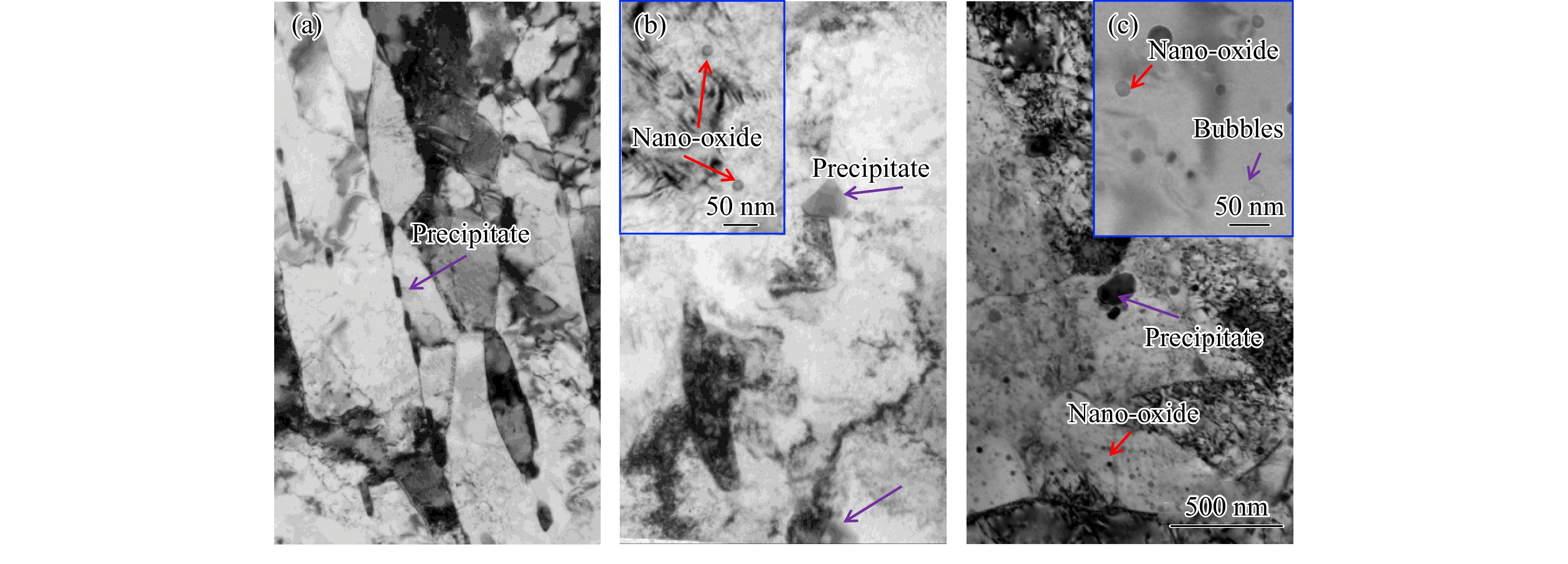

The microstructures of as-received three steels are shown in Fig. 1(a~c), respectively. The typical structures of SIMP steel [Fig. 1(a)] are composed of long martensite laths with mean size of 1.05 μm and the precipitation phases gathering mainly along grain boundaries[10]. Significant nano-oxide particles can be observed in both as-received Eurofer-ODS and MA956 steels. The mean size and density of the nano-oxide particles are 4.13 nm and 2.44×1023 m−3 for Eurofer-ODS steel, and 10 nm and 5×1021 m−3 for MA956 steel[11-12], respectively. In addition, a few of precipitates are also found in the Eurofer-ODS and MA956 steels as marked with purple arrows, and the mean density of the precipitates is slightly larger in the former. The main difference between these two ODS steels is that the grain size of MA956 is about 100 μm, but only 0.9 μm for Eurofer-ODS steel[13-14]. Moreover, some Ar gas bubbles formed during heat treatment are observed in MA956 steel rather than Eurofer-ODS steel[15].

-

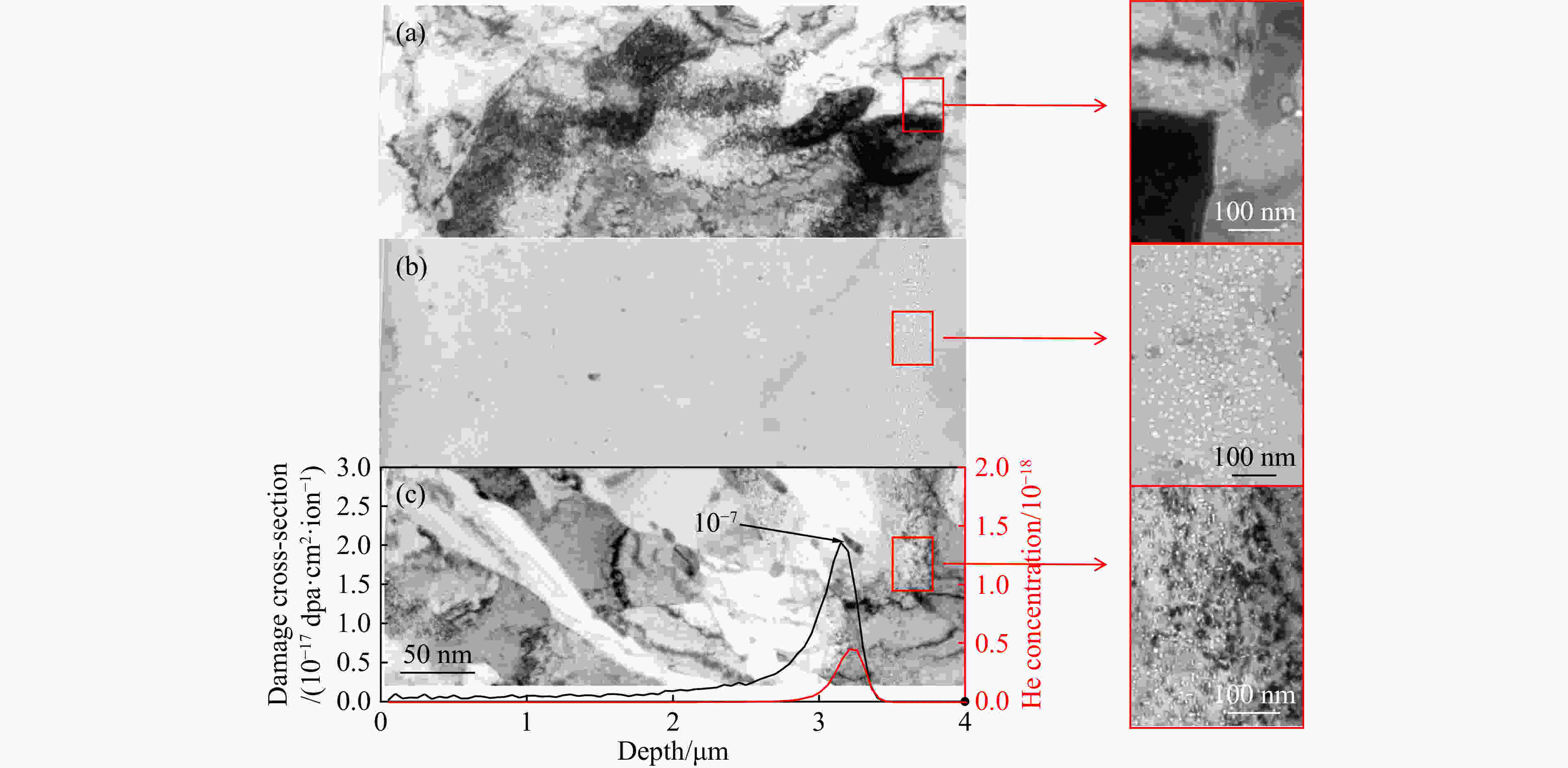

Fig. 2(a~c) shows the distribution of bubbles with depth in the three steels irradiated at 500 °C. The peak zones of He bubbles concentration for all of the materials are located in the depth range of 3.4~3.7 μm which goes even deeper compared to the result of SRIM simulation. The possible explanation is that the change of the material density caused by irradiation defects is not considered during the SRIM calculation. The production of high density He bubbles leads to seriously irradiation swelling and reduced local density of the material. As a result, the peak of He ions deposition moves to a deeper zone[16].

Figure 2. (color online)Typical microstructure of He bubbles with depth distribution and their partial enlarged details in (a) Eurofer-ODS steel, (b) MA956 steel, (c) SIMP with the fluence of 1×1017 ions/cm2 He at 500 ℃.

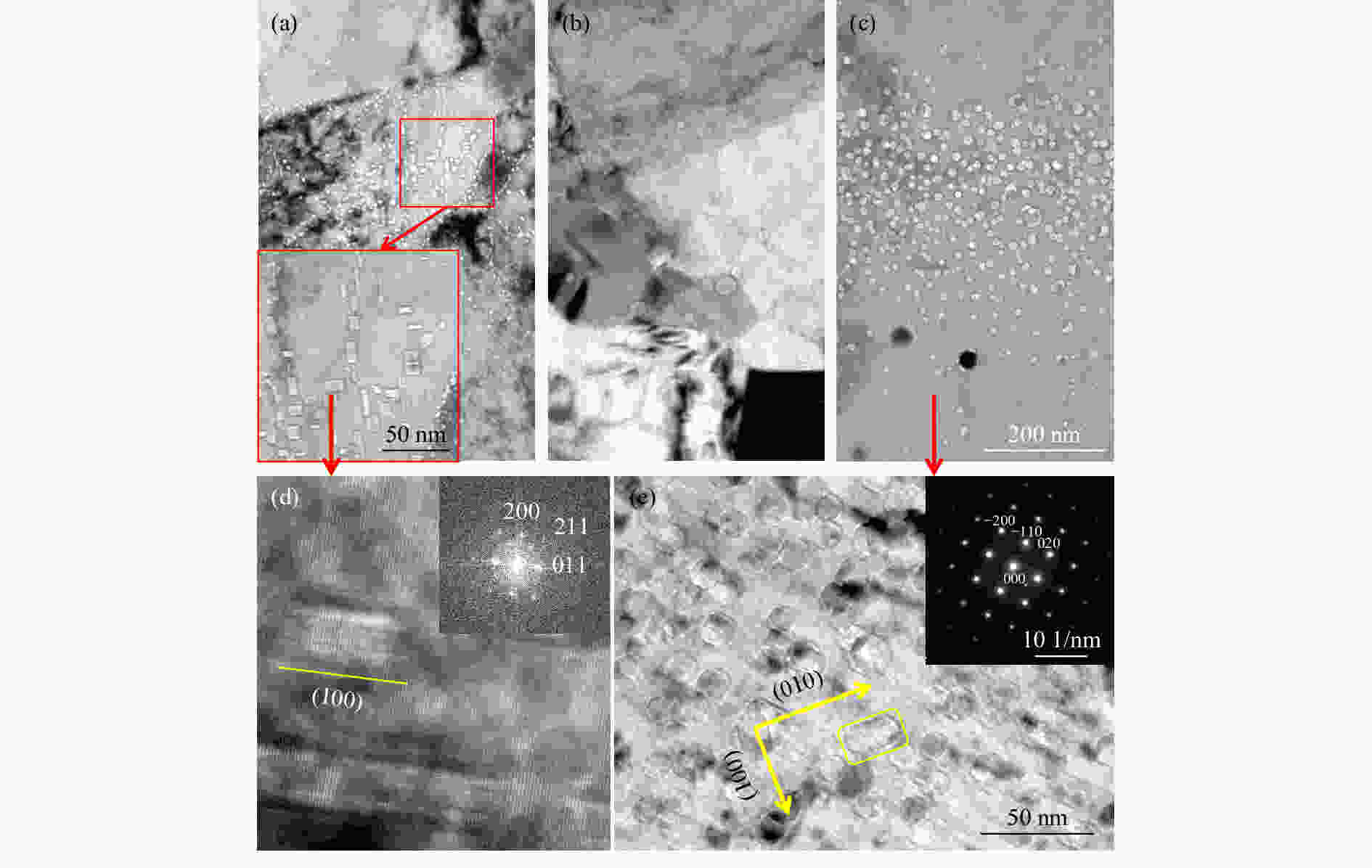

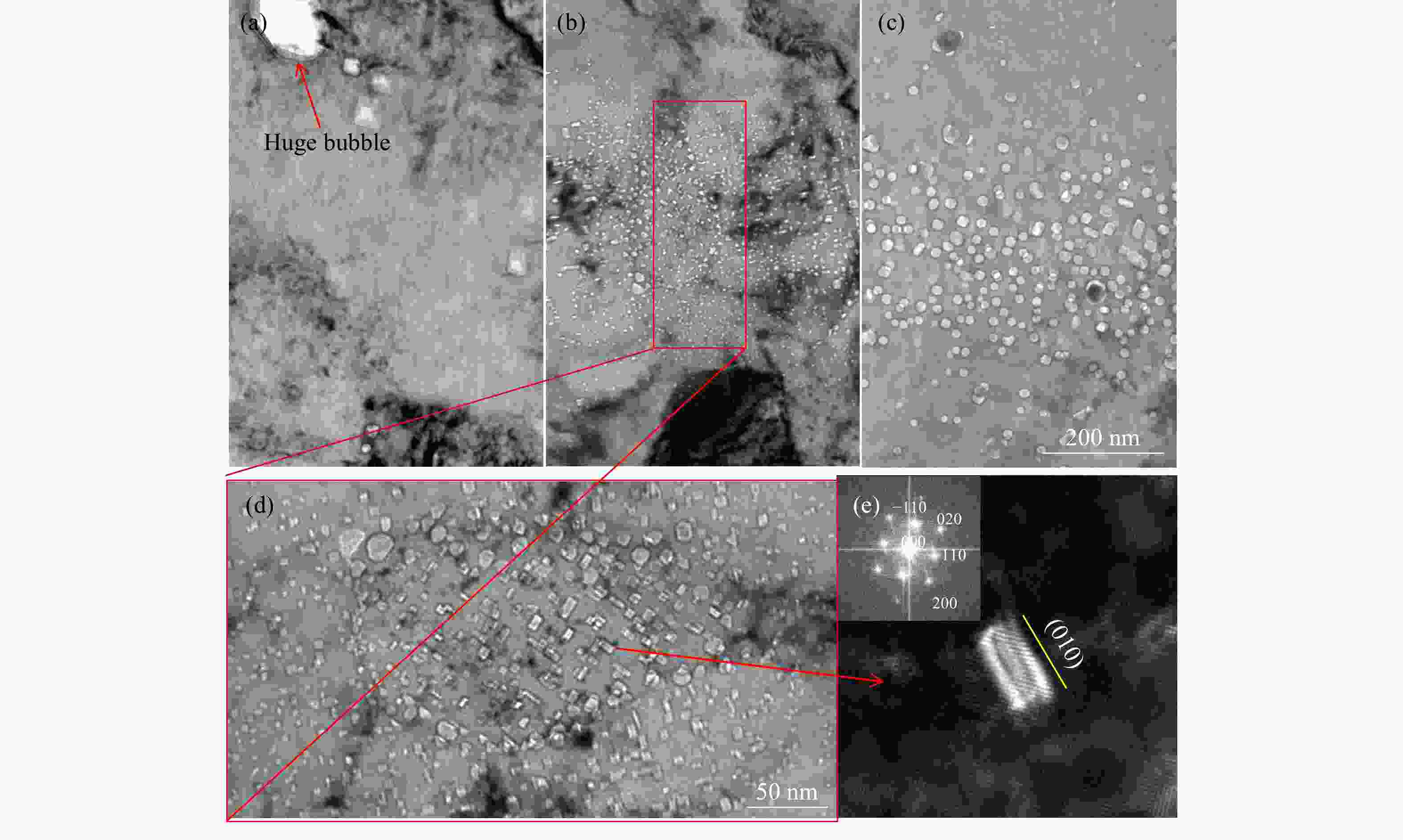

Typical morphologies of the He bubbles in the peak damage region for the three steels under 1×1017 ions/cm2 He ions implantation at 500 and 600 °C, respectively, are shown in Fig. 3 and Fig. 4. Firstly, at the temperature of 500 °C, faceted He bubbles with high density nucleate and coarsen in SIMP steel. High resolution transmission electron microscopy (HRTEM) image [Fig. 3(d)] indicates that these He bubbles distribute along the {100} plane. The nearly circular bubbles with low density are found in Eurofer-ODS steel[Fig. 3(b)]. In MA956, most of the high-density He bubbles are approximately spherical[Fig. 3(c)], except for a few faceted bubbles [Fig. 3(e)]. When the temperature rises to 600 °C, some extremely large He bubbles appear in SIMP steel [the red arrow in Fig. 4(a)]. For Eurofer-ODS steel, high-density and small-size faceted He bubbles are observed[Fig. 4(b)]. It can be verified that these faceted He bubbles also distribute along the {100} plane through HRTEM observation[Fig. 4(e)]. Dense and nearly spherical He bubbles are observed in MA956 steel [Fig. 4(c)], and the average size of these He bubbles is larger than that at 500 °C.

Figure 3. (color online)TEM images of He bubbles in the peak damage region for (a) SIMP, (b) EU-ODS, (c) MA956 under 1×1017 ions/cm2 He ions implantation conditions at 500 °C, and (d) high resolution image with its inverse Fourier transform pattern for He bubbles in SIMP steel, (e) high magnification image of He bubbles in MA956 with selected electron diffraction pattern.

Figure 4. (color online)TEM images of He bubbles in the irradiation damage zones for (a) SIMP, (b) EU-ODS, (c) MA956 under 1×1017 ions/cm2 He ions implantation conditions at 600 °C and (d) high magnification image and (e) high resolution image with its inverse Fourier transform pattern for He bubbles in Eurofer-ODS.

-

The morphology of facet He bubbles can be predicted by both anisotropy of the surface energy and minimization of the total surface energy of He bubbles[17]. The anisotropy of surface energy is determined by two factors: the pressure inside the He bubble and its surface tension[18]. When the internal pressure is less than the equilibrium pressure, He bubbles tend to be the shape of cubes in order to minimize surface energy. Because of the anisotropy of the surface energy, the cubic He bubbles tend to be arranged along a specific direction. In present study, the cubic He bubbles in the SIMP and EU-ODS steels preferentially distribute parallel to the {100} planes, indicating that the energy required for He bubble to grow on {100} planes is the lowest. Yan et al. [19] also pointed out that He bubbles tend to distribute along the {100} inertia planes in the bcc structure. Except for a few cubic He bubbles paralleled to the {100} planes, most of the He bubbles are truncated square with the mean size of about 20 nm in the MA956 steel. The shape of He bubbles was observed in different directions of TEM images, nearly all of them were truncated squares, resulting in that He bubbles in MA956 steel were almost roundish-cubes, as seen in Fig. 4(c). Compared to the cube morphology, the increased internal pressures and the reduced anisotropy of the surface energies in roundish-cube He bubbles make the shape tend to be spherical.

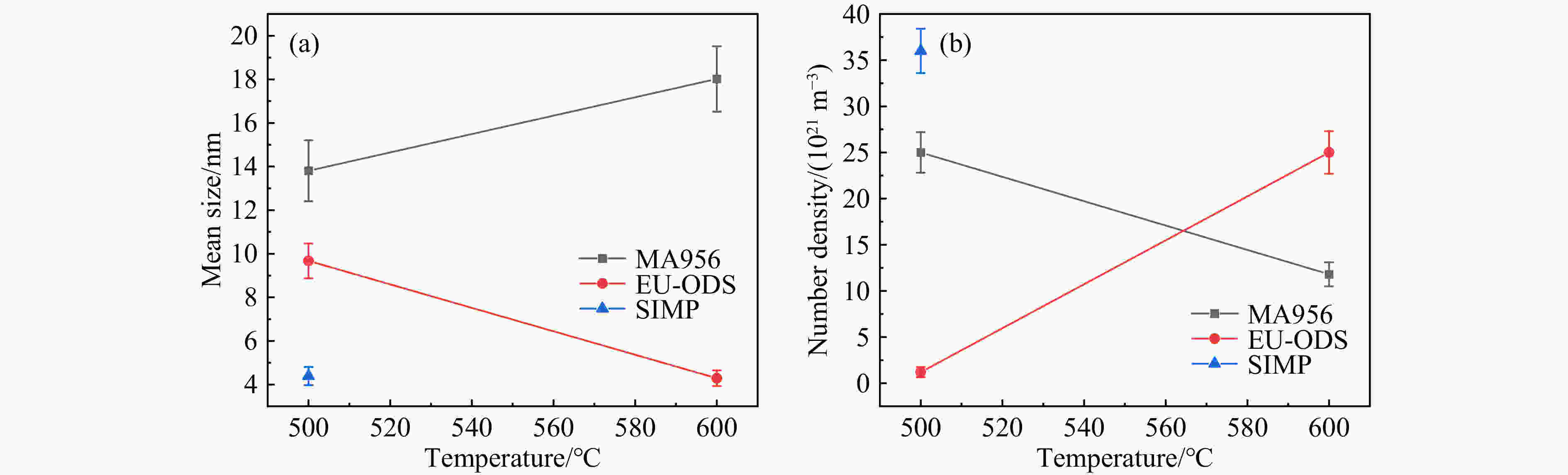

The mean size and number density statistic results of the He bubbles at the irradiation damage zone of the three samples are shown in Fig. 5. There are only very large bubbles or internal cracks in SIMP steel with 1×1017 He ions/cm2 injection at 600 °C, so no statistical results are given in this situation. At 500 °C, the mean sizes of He bubbles in MA956, Eurofer-ODS and SIMP steels are concentrated at the range of 13~15 nm, 9~11 nm, and 4~6 nm, respectively. There are high bubble densities both in MA956 and SIMP steels, while it is relatively smaller in Eurofer-ODS steel. When the temperature rises to 600 °C, the mean size of He bubbles in MA956 steel increases to 16~18 nm, but the number density decreases relatively as compared to 500 °C. For SIMP steel, the density of He bubbles decreases significantly compared to 500 °C. While there are large size bubbles even bigger than 100 nm in the sample. Although the average size of the He bubbles in Eurofer-ODS steel decrease, the increased bubble density promotes the swelling. Generally speaking, the resistance properties to irradiation swelling for the three steels are reduced with the increased temperature.

-

The heterogeneous He bubbles distributions in both SIMP and Eurofer-ODS steels are found at 500 °C, as shown in Figs. 6(a, c). The bubble density at the interface (GBs or precipitates surface) is significantly higher than that in the matrix. In addition, the phenomenon is also found in Eurofer-ODS steel [Fig. 6(d)] irradiated at 600 °C. However, the distribution of He bubbles in MA956 steel is almost homogeneous except for a few He bubbles attaching to the nano-oxides, which only slightly affect the size and distribution of He bubbles in these two irradiation conditions, as shown in Fig. 6(b). This means that the effect of grain boundary or precipitation is not pronounced in MA956 compared to SIMP and Eurofer-ODS steel due to the different size of grain boundary and density of precipitate among these three materials. In general, the smaller size and the greater density of defects have an influence on the nucleation and growth of He bubbles via providing large effective interfaces in the matrix which can absorb point defects during irradiation. Because the grain size of MA956 is much larger and the precipitate density is smaller than that of the SIMP and Eurofer-ODS, the effects of grain boundary and precipitate on the nucleation and growth of He bubbles in MA956 steel are not obvious. It can be found from the literature[15, 20-21] that the precipitated phase surfaces and GBs can be used as the centers of bubble nucleation, where the probability of bubble nucleation is larger than that in matrix. On the other hand, they are neutral sinks for point defects such as vacancies and interstitials. These point defects will be captured at these sinks at the same time, so the recombination probability of these defects is increased causing the decreased supersaturated vacancy concentration. Furthermore, the growth of He bubbles will be inhibited by He atoms migrating outside of the three materials because of the higher implanted temperature, which can to a certain extent reduce the swelling.

-

This study has investigated the swelling behavior of SIMP, Eurofer-ODS and MA956 steels under the implantation condition of 2 MeV He ions to the fluence of 1×1017 ions/cm2 at 500 and 600 °C. The three materials show different swelling behaviors under the above irradiation conditions. Some key conclusions include: the SIMP and Eurofer-ODS steels have better resistance to radiation swelling than MA956 steel at 500 °C. The He bubbles in SIMP steel are in facet shapes with orientation along the {100} type plane attributed to anisotropy of surface energy. When the temperature rises to 600 °C, Eurofer-ODS steel exhibits excellent resistance to radiation swelling, and He bubbles present the same shape and orientation as in SIMP steel at 500 °C. It is also observed that some of very large bubbles begin to appear in SIMP steel. The mean size of bubbles in MA956 increases with the increased temperature. In general, the resistances to swelling of all the three materials are deteriorated with the increase of temperature. It is assumed that the original precipitates and grain boundaries in EU-ODS and SIMP steels can effectively inhibit the growth of He bubbles, and the effect of nano-structures on nucleation and growth of He bubbles is limited in MA956 steel exposed with extremely high He production.

Effect of Nanostructures on Bubbles Nucleation and Growth in F/M and ODS Steels Exposed with High Helium Fluence

-

摘要: 利用LEAF装置提供的2 MeV的He离子,在500和600 °C分别对新型F/M钢-SIMP钢和ODS钢(MA956和Eurofer-ODS钢)注入1×1017 ions/cm2的高通量He离子,借助透射电子显微镜,表征了辐照后三种材料的肿胀行为,验证了各材料中纳米微结构(晶界,析出相和纳米氧化物)对辐照后He泡成核和长大的影响。结果表明,基于材料中晶界和析出相对He泡生长的抑制作用,温度为500 °C时,SIMP和Eurofer-ODS钢表现出较高的抗辐照肿胀性能,而MA956中纳米界面He泡成核和长大作用不明显,表现出较差的抗辐照肿胀性能;此外,温度为600 °C时,Eurofer-ODS钢由于其晶界和氧化物界面的较强作用,表现出较好的抗辐照肿胀性能。总体来说,在高He通量注入条件下,材料中纳米结构的存在会抑制He泡长大的过程,但不同材料中纳米结构对He影响作用不同。

-

关键词:

- nanostructure /

- steel /

- He bubble /

- nucleation and growth /

- TEM

Abstract: A new type of F/M steel (SIMP steel) and two kinds of ODS steels (MA956 and Eurofer-ODS steels) were irradiated by 2 MeV He ions to fluence of 1×1017 ions/cm2 at 500 and 600 °C. After irradiation, swelling behaviors and effect of nanostructures (such as grain boundaries, precipitates and nano-oxide particles) on the nucleation and growth of He bubbles were studied by transmission electron microscope. The results show that both SIMP and Eurofer-ODS steels exhibit better swelling resistance than MA956 ODS steel at 500 °C, because the grain boundaries or precipitates pronouncedly inhibit the growth of He bubbles. The Eurofer-ODS steel shows best swelling resistance due to the inhibition of He bubbles growth by the grain boundary and oxide interface at 600 °C. The present work shows that nanostructures in materials inhibit the process of He bubble growth under high He fluence conditions, but the degree of inhibition varies with different materials.-

Key words:

- nanostructure /

- steel /

- He bubble /

- nucleation and growth /

- TEM

-

Figure 3. (color online)TEM images of He bubbles in the peak damage region for (a) SIMP, (b) EU-ODS, (c) MA956 under 1×1017 ions/cm2 He ions implantation conditions at 500 °C, and (d) high resolution image with its inverse Fourier transform pattern for He bubbles in SIMP steel, (e) high magnification image of He bubbles in MA956 with selected electron diffraction pattern.

Figure 4. (color online)TEM images of He bubbles in the irradiation damage zones for (a) SIMP, (b) EU-ODS, (c) MA956 under 1×1017 ions/cm2 He ions implantation conditions at 600 °C and (d) high magnification image and (e) high resolution image with its inverse Fourier transform pattern for He bubbles in Eurofer-ODS.

Table 1. Details of chemical composition of SIMP, Eurofer-ODS, and MA956 steels (%).

Steels Fe Cr C Mn S W V Ta Si P Y2O3 Ni Al Ti Mo SIMP#1 Bal 10.24 0.22 0.52 0.0043 1.45 0.18 0.12 1.22 0.004 Eurofer-ODS#2 Bal 8.70 0.11 0.44 0.004 1.00 0.19 0.10 0.30 MA956#3 Bal 19.93 0.023 0.09 0.008 0.008 0.006 0.51 0.04 4.75 0.39 0.02 #1 SIMP: normalized at 1 040 °C for 30 min and tempering at 760 °C for 90 min.

#2 Eurofer-ODS: normalized at 1 150 °C for 60 min, tempering at 750 °C for 120 min.

#3MA956: canned and extruded at 1 100 °C, hot-rolled for 240 min, reheating to 1 100 °C for 30 min, hot-rolled.Table 2. Detailed parameters of He ions implantation experiment.

Sample Ion Energy/

MeVTem/℃ Fluences/

(ions·cm−2)SIMP/EU-ODS/MA956 He 2 500 1×1017 600 -

[1] KLUEH R L, NELSON A T. Journal of Nuclear Materials, 2007, 371(1-3): 37. doi: 10.1016/j.jnucmat.2007.05.005 [2] ODETTE G R. O. Journal of Nuclear Materials, 1988, 155-157: 921. doi: 10.1016/0022-3115(88)90442-4 [3] KLUEH R L. Transactions of The Indian Institute of Metals, 2009, 62(2): 81. doi: 10.1007/s12666-009-0011-3 [4] WAS G S, ALLEN T. Materials Characterization, 1994, 32: 239. doi: 10.1016/1044-5803(94)90101-5 [5] KURTZ R J, ALAMO A, LUCON E, et al. Journal of Nuclear Materials, 2009, 386-388: 411. doi: 10.1016/j.jnucmat.2008.12.323 [6] ZHANG X, MEI X, CAO X, et al. Journal of Nuclear Materials, 2018, 509: 496. doi: 10.1016/j.jnucmat.2018.07.038 [7] MAZUMDER B, BANNISTER M E, MEYER F W, et al. Nuclear Materials and Energy, 2015, 1: 8. doi: 10.1016/j.nme.2014.11.001 [8] ZIEGLER J F, ZIEGLER M D, BIERSACK J P. Nucl Instr and Meth B, 2010, 268(11-12): 1818. doi: 10.1016/j.nimb.2010.02.091 [9] STOLLER R E, TOLOCZKO M B, WAS G S, et al. Nucl Instr and Meth B, 2013, 310: 75. doi: 10.1016/j.nimb.2013.05.008 [10] LI B S, WANG Z G, WEI K F, et al. Fusion Engineering and Design, 2019, 142: 6. doi: 10.1016/j.fusengdes.2019.04.049 [11] FU J, DAVIS T P, KUMAR A, et al. Materials Characterization, 2021, 175: 111072. doi: 10.1016/j.matchar.2021.111072 [12] ZHANG C H, KIMURA A, KASADA R, et al. Journal of Nuclear Materials, 2011, 417(1-3): 221. doi: 10.1016/j.jnucmat.2010.12.063 [13] DAS A, CHEKHONIN P, ALTSTADT E, et al. Journal of Nuclear Materials, 2020, 533: 152083. doi: 10.1016/j.jnucmat.2020.152083 [14] BAKER B W, MCNELLEY T R, BREWER L N. Materials Science & Engineering A, 2014, 589: 217. doi: 10.1016/j.msea.2013.09.092 [15] ZHANG C H, JANG J, CHO H D, et al. Journal of Nuclear Materials, 2009, 386-388: 457. doi: 10.1016/j.jnucmat.2008.12.161 [16] GETTO E, SUN K, TALLER S, et al. Journal of Nuclear Materials, 2016, 477: 273. doi: 10.1016/j.jnucmat.2016.05.026 [17] NIWASE K, EZAWA T, FUJITA F E, et al. Radiation Effects, 1988, 106(1-2): 65. doi: 10.1080/00337578808013729 [18] NIWASE K, EZAWA T, TANABE T, et al. Journal of Nuclear Materials, 1988, 160(2-3): 229. doi: 10.1016/0022-3115(88)90052-9 [19] YAN Z, YANG T, LIN Y, et al. Journal of Nuclear Materials, 2020, 532: 152045. doi: 10.1016/j.jnucmat.2020.152045 [20] WANG X, YAN Q, WAS G S, et al. Scripta Materialia, 2016, 112: 9. doi: 10.1016/j.scriptamat.2015.08.032 [21] BHATTACHARYA A, ZINKLE S J. Comprehensive Nuclear Materials, 2020, 1: 406. doi: 10.1016/B978-0-12-803581-8.11599-1 -

下载:

下载:

甘公网安备 62010202000723号

甘公网安备 62010202000723号